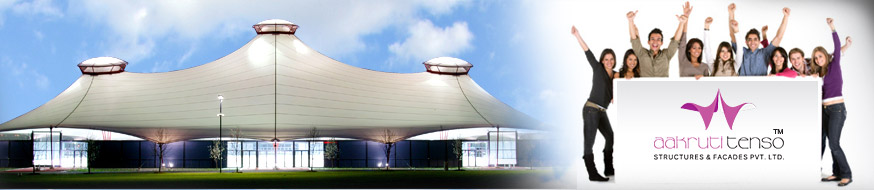

Tensile Canopy Manufacturer- Food Court - Rajkot Gujrat

|

A well known Retail Chain Brand, setting up 40,000 sq. ft plus independent structure at one of the most scene tic location in Heart of Raipur, wanted to develop Multi-Brand food court on the Terrace.

In 1 st Phase, Half terrace of roughly 12000 sq. feet is to be developed.

The Challenge was to offer a stable structure for otherwise windy location with rough Landscape facing a Huge Lake. The Structure being billed for the Retailing had under gone lots of changes. Especially a whole Floor Plate was added on existing columns as a afterthought once the basement & columns were casted.

At the Time when Aakruti Tenso (Tensile Structure Manufacturer) was appointed to Design, develop, Fabricate suitable tensile fabric Roof for the Food court, the Terrace was already casted & final water proofing was being carried out.

The Total open Area of a Food Court at Rajkot, Gujarat to be covered was roughly 1080 sq. meters or 12000 sq. ft.

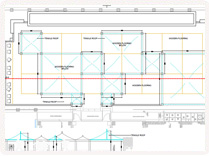

Our Tensile Structure Fabricators team decided to transfer all the loads directly to existing columns (projecting out above the Terrace level by 300 mm), without disturbing beams or slabs. There were only 3 intermediate columns present with 12 peripheral columns.

We proposed a form which was Combination of a Vault & Large span Cones, avoiding flat Fabric regions usually unavoidable in case of cones with Rectangular Base. A walk way was introduced to connect staircase to the main Food court overseeing schematic lake. A kitchen Area in Multi point Hyper fabric form ensured enough ventilation.

Hence the Food court with 4 connected cones (Twin cones, 2 sets) having inclined mast supporting bail Ring., walkway, & Kitchen Area were integrated into a single Design form.

Detailed Analysis of the structure was carried out with Internationally acknowledged FEM software. In absence of Local codes for Governing construction of Tensile Canopy structures, British standards were followed to generate wind loads depending on geometry, height of structure, height from sea level, dist from sea, surface roughness, topology, etc. The wind pressure for wind speed of 110 km/Hr, followed by various factors to take care of the variable mentioned above was used.

Once structure was analyzed, the dimensional detailing of each individual structural member were carried out after STAAD analysis depending on the max. Load generated in load combinations. Auto cad 2011 was used for Detailing- drafting purposes.

The primary structure was Fabricated from 20 different Trusses made from tubular sections of various sizes (ERW pipes C class Tata), as the beams. Where as vertical columns were fabricated from round hollow section of 219 mm die X 8 mm thickness. The extra Long radial members supporting the mast were Dia. 165 X 6.4 mm pipes (Pinned Joint).

The top ring Dia. 1500mm supported on Dia. 165 mm Mast which in turn was supported by 4 radial struts men tined above. The Bail Ring cap was also fabricated in form a Mini Cone from the same Fabric.

The 950 GSM, PVC coated fabric was patterned Radially in all 36 patterns, depending on the size of the cone. To absorb higher stresses towards the Ring center the fabric was reinforced with another layer of 950 GSM membrane patterned in floral shape.

The fabric was fixed on the Top edge of the Beams with the help of clamping stainless steel strips of 40 mm X 8 mm, separated by Neoprene rubber Gaskets, with help of M10 X 60 Nut- Bolts. The fabric was clamped to the central Bail Ring with help of Stainless steel Nut bolts.

The Foundations on top of the Columns were fixed with Help of Hilti Make mechanical fasteners. The steel structure was fabricated at the site. The heavy members were handled manually with help of Tools & fixtures. (Crane access was not possible). The fabrication was completed in 6 weeks.

Local Vendor was appointed to carry out epoxy coating Painting. By the time the Painting was completed the Fabric fabrication process was side by side completed in 2 weeks.

The fabric was delivered at site. Now the challenging Task of lifting Volumes, heavy 1200 Kg fabric to the Terrace level without a crane was taken. The fabric in packed condition travelled to the Ring top almost manually in 7 days. Once on top fabric was fixed to bail rings initially, the edges of the fabric were clamped on top of beams subsequently. The fairly routine process of lifting bail ring was under taken to stretch the fabric to designed Pre- tension.

The walk ways & the kitchen Area posed no great challenge. The edges of the connecting fabric were sealed to ensure water tightness.

The project was completed well within time span of 60 days in Rajkot, Gujarat. The steel structure was installed at site in 7 Days even in unfavorable conditions. The Fabric Installation was carried out in Rainy weather. Final fabric Installation took just 72 hours back to back.